The relative speed of piezoelectric and electromagnetic actuation depends heavily on the specific application and the design of the devices involved. Piezoelectric actuators excel in generating extremely rapid, high-precision movements over very short distances. This is because they respond directly to an applied voltage, resulting in near-instantaneous displacement. In contrast, electromagnetic actuators, such as solenoids or motors, involve the generation of a magnetic field, which then interacts with a moving part. This process introduces inherent time delays associated with inductance, inertia, and mechanical linkages. While electromagnetic systems can achieve higher power and larger displacements, piezoelectric systems often exhibit significantly faster response times for micrometer-scale applications.

This speed advantage of piezoelectric technology is crucial in various high-speed applications, including precision positioning systems for micro-manufacturing, advanced microscopy, inkjet printing, and some types of ultrasonic transducers. The ability to achieve extremely rapid and precise control offers significant improvements in efficiency and performance compared to systems relying on electromagnetic actuation in these niche areas. Historically, the development of piezoelectric materials and their integration into devices has been instrumental in pushing the boundaries of speed and precision in miniature actuation systems.

Further exploration will delve into the underlying principles governing the actuation mechanisms of both technologies, comparing their performance characteristics in various contexts, and examining the specific applications where each technology holds a distinct advantage. This will include discussions of power consumption, displacement capabilities, and overall system design considerations.

Images References

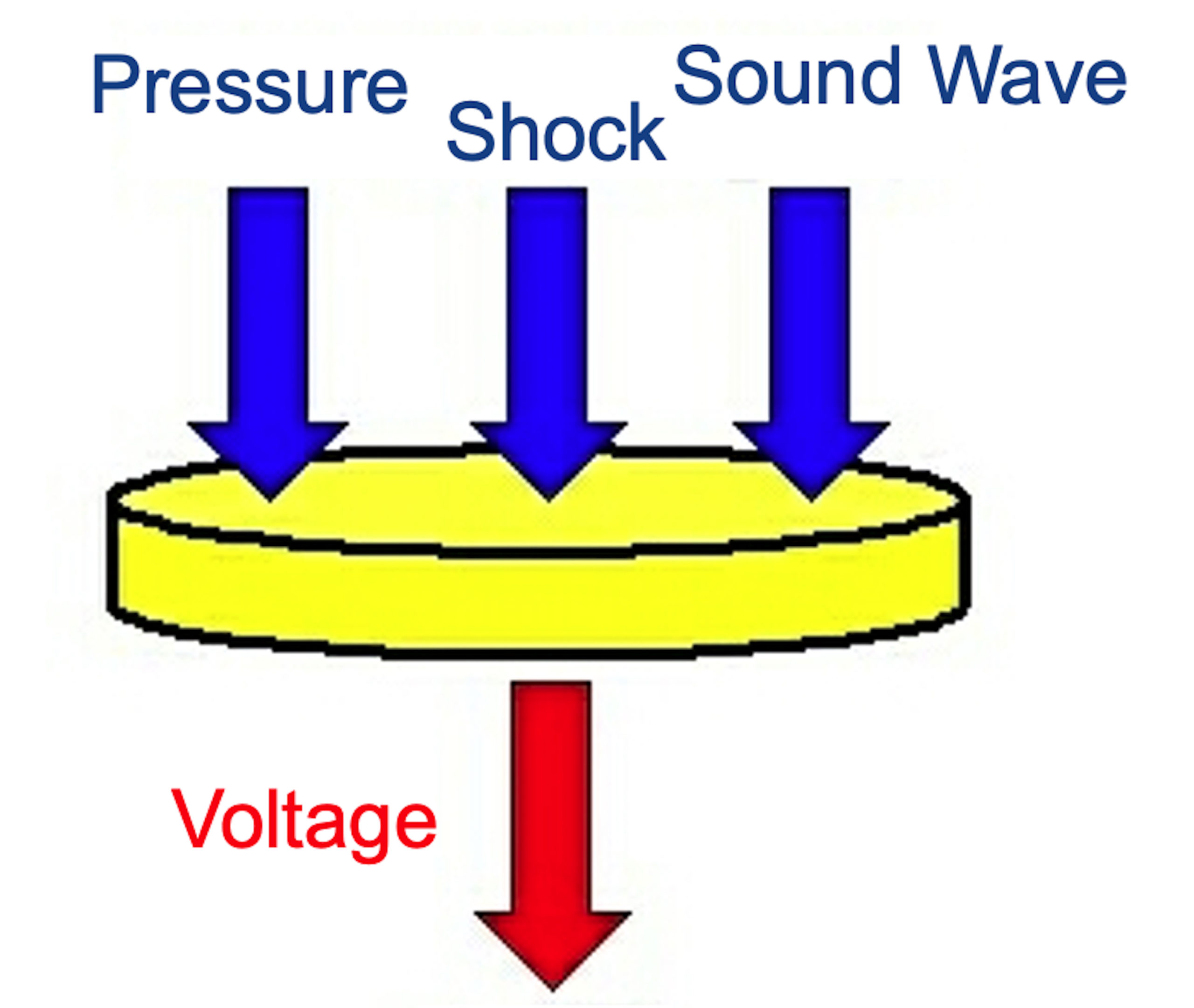

Source: www.eeworldonline.com

Principles, selection and design with piezoelectric actuators

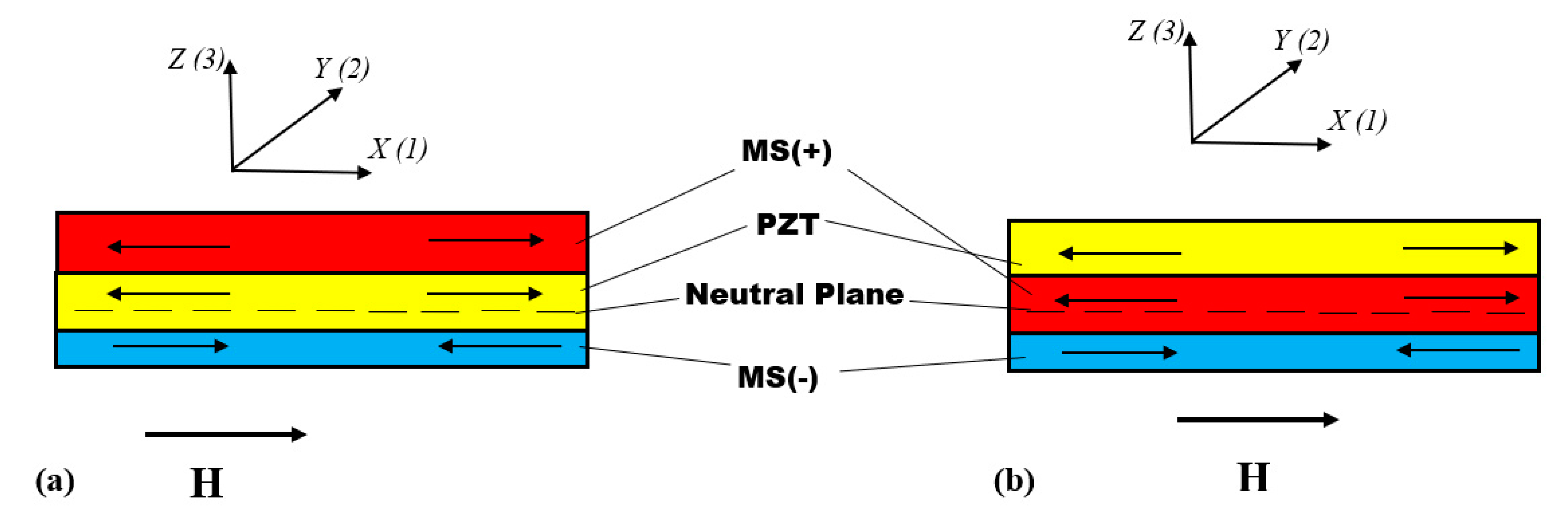

Source: www.mdpi.com

J. Compos. Sci. Free FullText Theory of Effect for

Leave a Reply