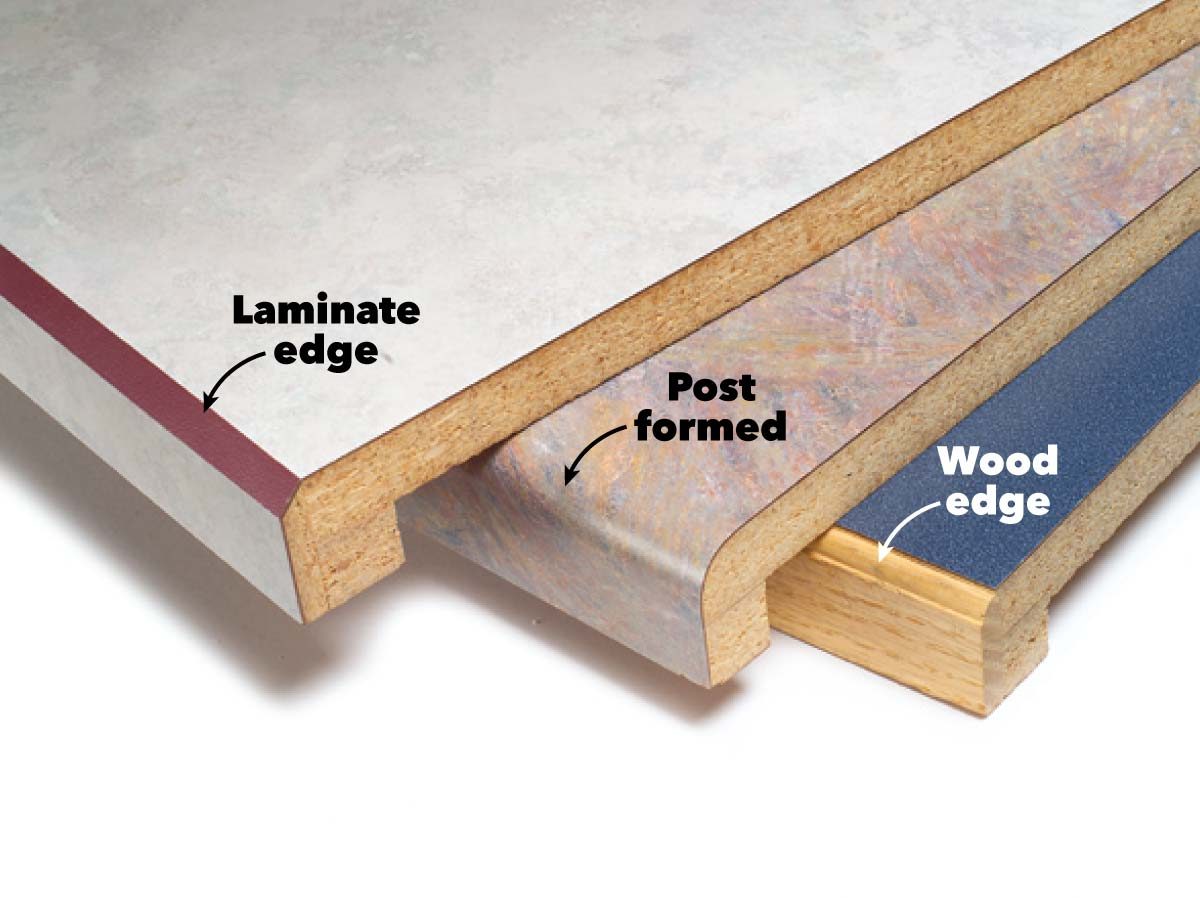

High-pressure laminate (HPL) is frequently applied to wood substrates, creating a composite material with a durable, decorative surface. This involves bonding a thin layer of decorative plastic laminate to a core of wood, often plywood or particleboard. The resulting material offers a balance of aesthetics and practicality, commonly seen in furniture, countertops, and wall cladding.

This manufacturing process provides significant advantages. The laminate’s protective layer enhances resistance to scratches, stains, moisture, and abrasion compared to untreated wood. The underlying wood core provides structural integrity. This combination results in a cost-effective, long-lasting material with diverse design possibilities. The technique has been widely adopted due to its versatility and ability to mimic more expensive materials while maintaining relatively low maintenance requirements. Its widespread use reflects a long history of innovation in materials science and manufacturing.

Subsequent sections will delve into specific aspects of this composite material, including the manufacturing process, various applications, and considerations related to its lifespan and environmental impact.

Images References

Source: www.homequestionsanswered.com

What Is Plastic Laminate? (with picture)

Source: www.familyhandyman.com

Buying Countertops Plastic Laminates, Granite and Solid Surfaces

Leave a Reply