Valve system sealing relies heavily on gaskets, and paper-based options offer a cost-effective and often suitable solution for many applications. These components’ performance is dictated by several key characteristics, including material composition (e.g., type of paper, impregnating materials), thickness, internal and external dimensions, and tolerances. For example, a specific valve might require a gasket with a 2-inch diameter, 0.015-inch thickness, and manufactured to tight tolerances to ensure a leak-proof seal under high pressure. Other relevant specifications may include temperature resistance, chemical compatibility, and surface finish.

Proper gasket selection is critical for maintaining system integrity and preventing leaks, which can lead to operational downtime, environmental hazards, or even safety risks. The appropriate material and dimensions ensure a reliable seal, contributing to efficient system operation and extended equipment lifespan. Historically, advancements in paper-based gasket materials have led to enhanced performance and broader applicability in diverse valve systems across numerous industries.

Subsequent sections will detail the various factors influencing gasket selection, including material properties, dimensional considerations, relevant industry standards, and testing methodologies to determine suitability for specific operating conditions.

Images References

Source: maktrans.net

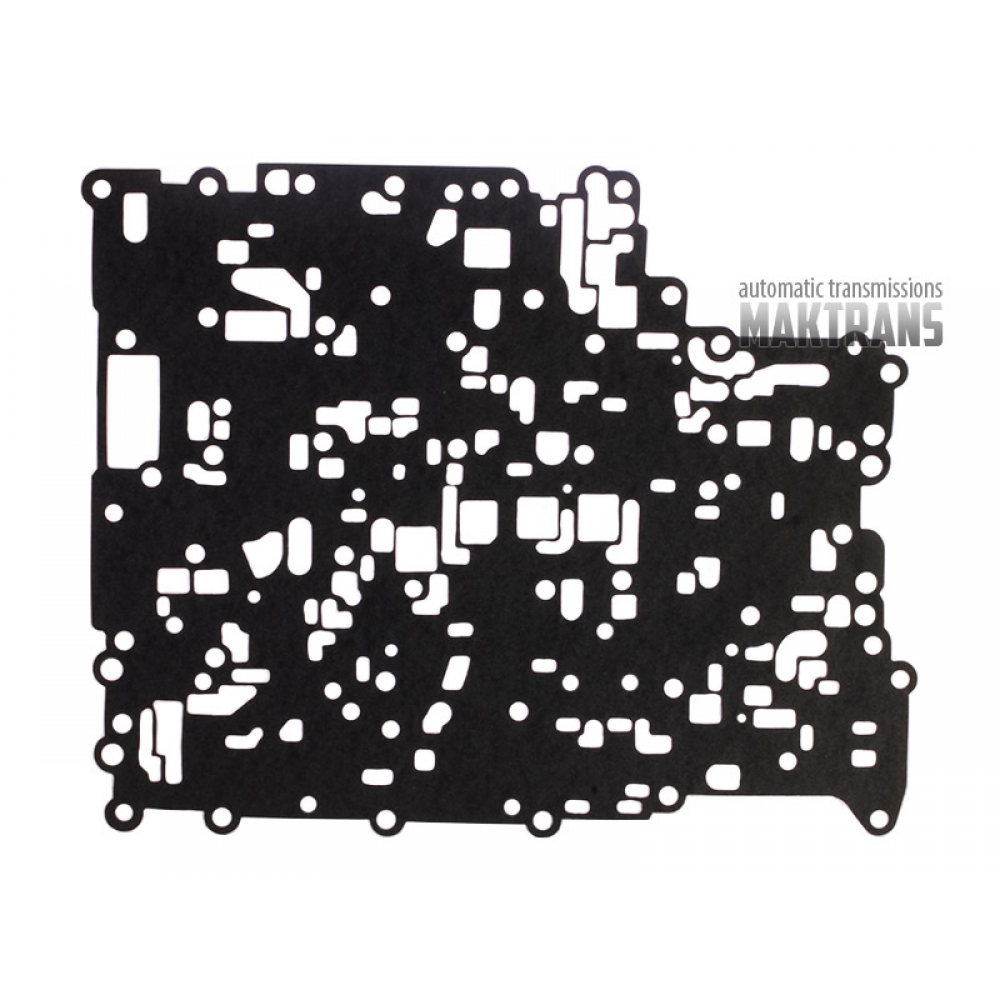

Valve body paper gasket N5 RE5R05A

Source: maktrans.net

Valve body paper gasket kit U760

Leave a Reply