Specialized software designed for controlling and managing individual spindles in a machining center or similar multi-spindle environment is crucial for optimizing production. This type of software offers precise control over parameters such as speed, feed rate, and tool selection for each spindle independently, enabling complex operations and enhanced efficiency. For example, in a multi-spindle lathe, this software might coordinate different operations simultaneously on a single workpiece, drastically reducing machining time compared to sequential processing.

The primary benefit lies in the ability to achieve high throughput and precision. By providing granular control over each spindle, manufacturers can reduce waste, minimize setup times, and increase the overall quality of the finished product. Historically, such sophisticated control was achieved through complex hardware systems; modern software solutions offer increased flexibility, easier programmability, and reduced cost of ownership. The development of this technology has significantly advanced the capabilities of automated manufacturing processes.

This understanding of advanced spindle control systems provides a foundation for exploring specific applications, including real-time monitoring, predictive maintenance, and integration with broader manufacturing execution systems (MES). The following sections will delve into these areas in greater detail.

Images References

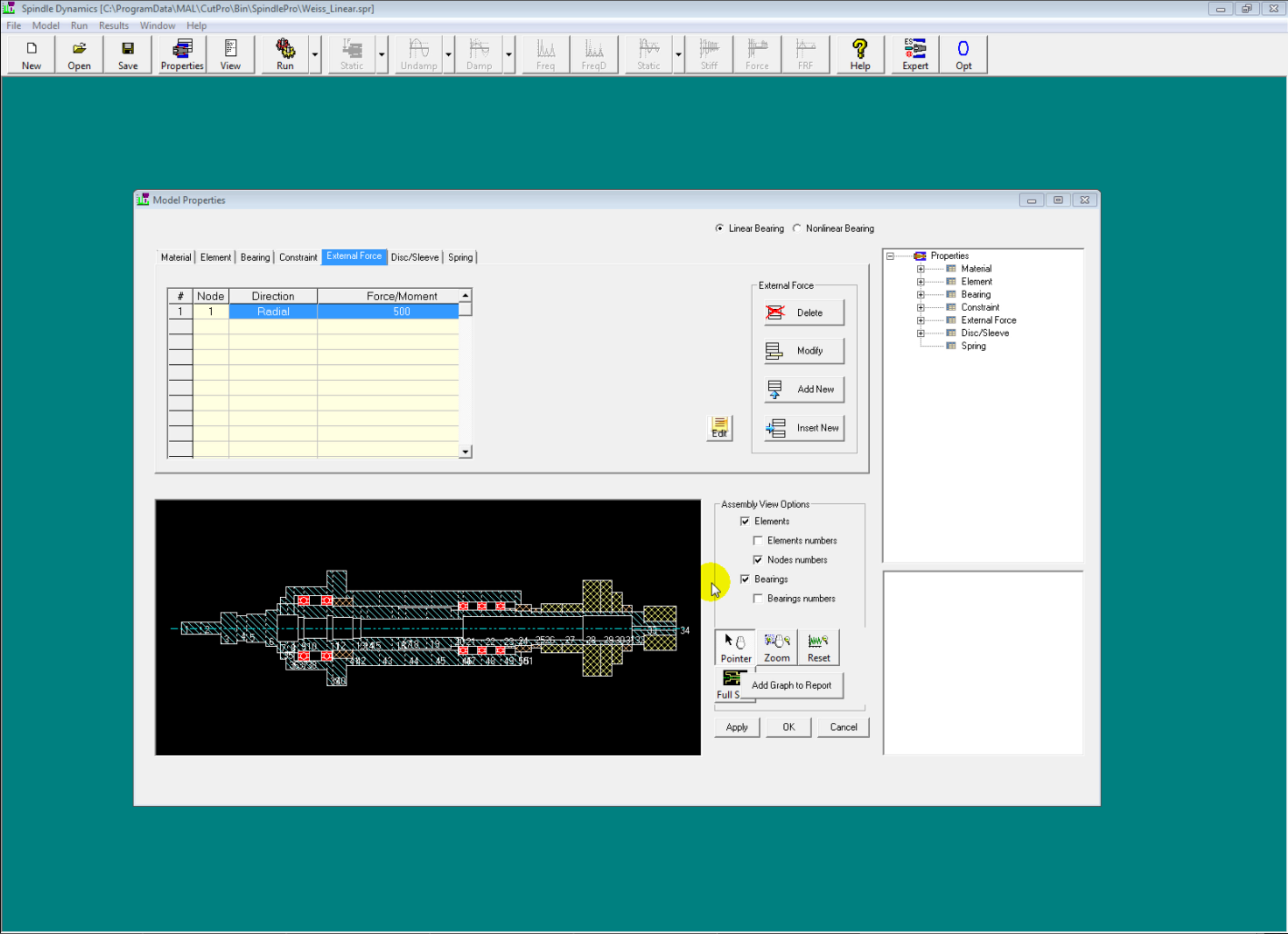

Source: www.malinc.com

SpindlePro CNC Spindle Design Software

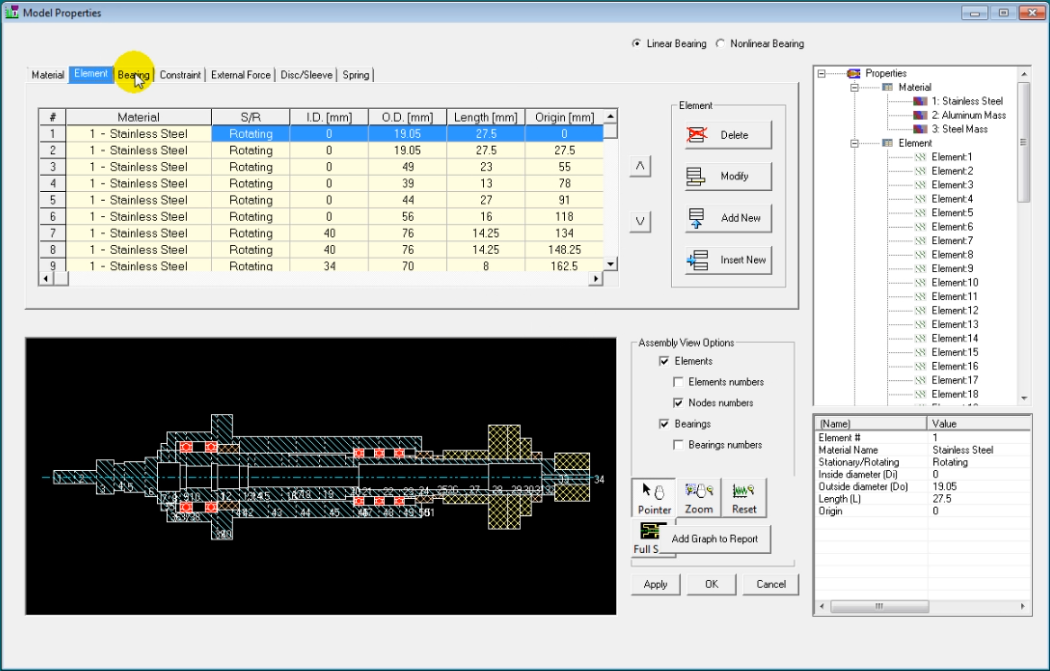

Source: www.malinc.com

SpindlePro CNC Spindle Design Software

Leave a Reply