A 134 needle, typically used in industrial sewing machines, features a specific part called the “shank.” This is the portion of the needle located immediately below the eye and above the needle body. It’s a cylindrical section, often with a distinct groove or flat area, designed to fit securely into the sewing machine’s needle clamp. The shank’s dimensions are crucial for proper alignment and secure gripping within the machine, preventing needle breakage or malfunction. The size and shape of this component vary slightly depending on the manufacturer and specific needle type.

The proper fit of this component is essential for optimal sewing performance. A secure grip minimizes vibration and needle deflection, leading to increased accuracy and stitch quality. Improper fit can result in skipped stitches, broken needles, and potential damage to the sewing machine itself. The design facilitates easy needle insertion and removal, minimizing downtime and improving efficiency within a production setting. This seemingly small element plays a vital role in the overall functionality and reliability of the industrial sewing process.

Understanding this component’s characteristics is foundational for selecting appropriate needles for various fabrics and sewing applications. Further discussion will focus on the selection criteria for appropriate needles, addressing fabric types, thread weights, and sewing machine capabilities.

Images References

Source: www.aliexpress.com

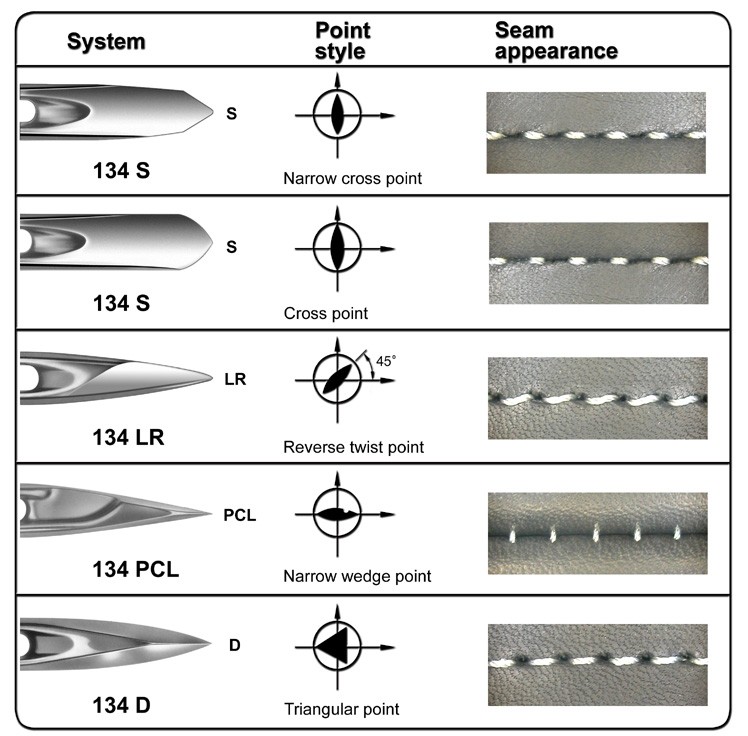

Size 125/20, 10 Leather Point Industrial Sewing Machines Needles 134LR

Source: www.garmentwork.com

134 PCL Cutting Point Needles LEATHER MACHINE SEWING NEEDLE เข็มจักร

Leave a Reply